Automation will play a big part in our future.

Adopting the latest technologies lets us design and build the best possible bodies.

Our high amount of investment in technology guarantees our quality. This also increases our factories efficiency and output. In the last few years, we have invested over £6m across our four factory locations. Today, we have the most advanced machine tools and production processes in the industry.

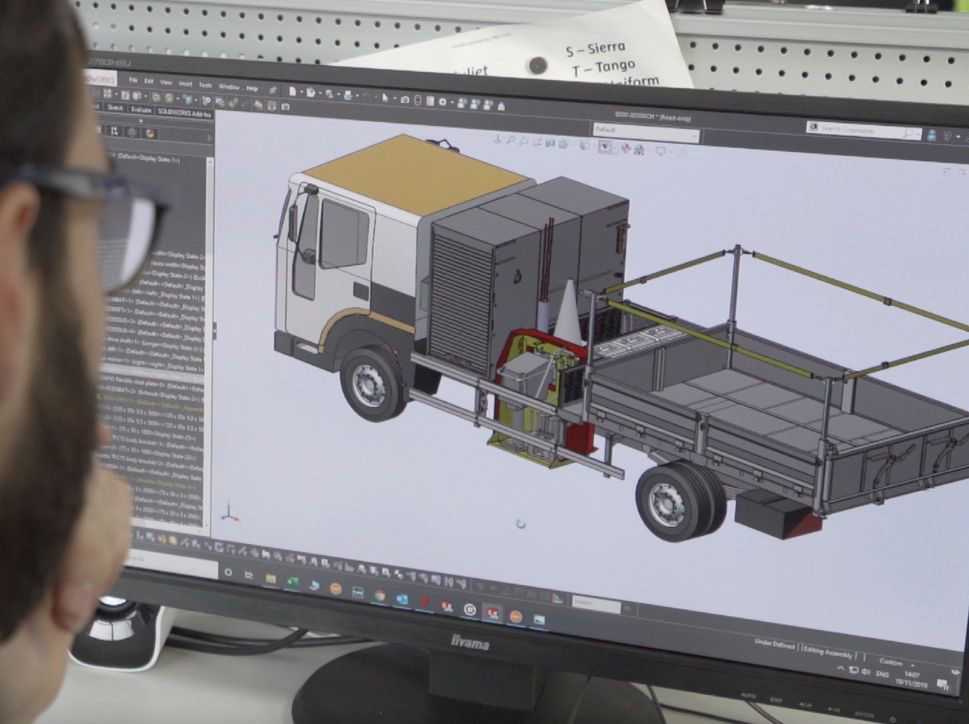

CAD and innovation

In the Engineering Department, software plays an enormous role in allowing us to provide engineering support to all aspects of the company. Having invested substantially in software, all of our parts are now modelled in 3D, using Solidworks. Sheet metal parts can then be processed, using Bysoft.

This allows us to unfold the parts and write press and laser programs from the office, ready for production. We are able to perform test simulations on our products using FEA software. This identifies potential problems before we cut metal as well as highlighting areas where we can make improvements to our designs.

Other software we have enables us to perform axle calculations to ensure the trucks can carry a full payload without overloading any axles. Software has changed the way we work and will continue to evolve

Engineering

Thompsons twenty years ago, was a very different company to the Thompsons of today. Apart from a couple of plasma cut profiles, everything was handmade, we had no Engineering department, no CAD software and there were no drawings. We now have 5 degree qualified engineers covering the various factories, providing support with design, press and laser programs, production paperwork, FEA simulations and purchasing.

Thompsons is now a modern company with modern equipment and engineering is crucial to its operations. I’m proud of how the department has progressed and excited about the possibilities in the future.

Prep, Paint and Finish

We have invested in our paint facilities at all locations in the UK. Shotblasting is essential for the highest possible finished quality. Plus our paint processes are as environmentally friendly as we can possibly make them. Thompsons quality always ensures maximum residuals.